WEAVING

At Cora Tex, we specialize in high-quality woven fabrics, crafted with precision and expertise. Our weaving facility integrates cutting-edge technology with skilled craftsmanship to ensure durable, versatile, and premium textiles for fashion, home furnishing, and industrial

Weaving Facilities & Capacity

Production Capacity: Approximately 25,000 – 50,000 meters per day

Fabric Widths: 122 cm to 360 cm

Loom Types:

100-200 air-jet looms for high-speed, efficient weaving

50-100 dobby and rapier looms for intricate fabric designs

Dyeing Capacity: Approximately 10,000 – 20,000 meters per day

Advanced Weaving Technology

High-Speed Air-Jet Looms – Delivering smooth, uniform fabrics with excellent durability, ideal for fashion, home textiles, and industrial use.

Dobby & Rapier Looms – Enabling intricate weaving patterns, customized textures, and premium-quality designs for specialized fabric needs.

Extended Width Weaving – Capable of producing wider fabrics up to 360 cm, ensuring seamless production for upholstery, bedding, and technical textiles.

Bulk Production Efficiency – Long piece lengths of up to 1000 meters per roll optimize large-scale manufacturing while maintaining consistency.

Precision & Sustainability – Automated monitoring systems reduce defects, while energy-efficient weaving techniques support eco-friendly production.

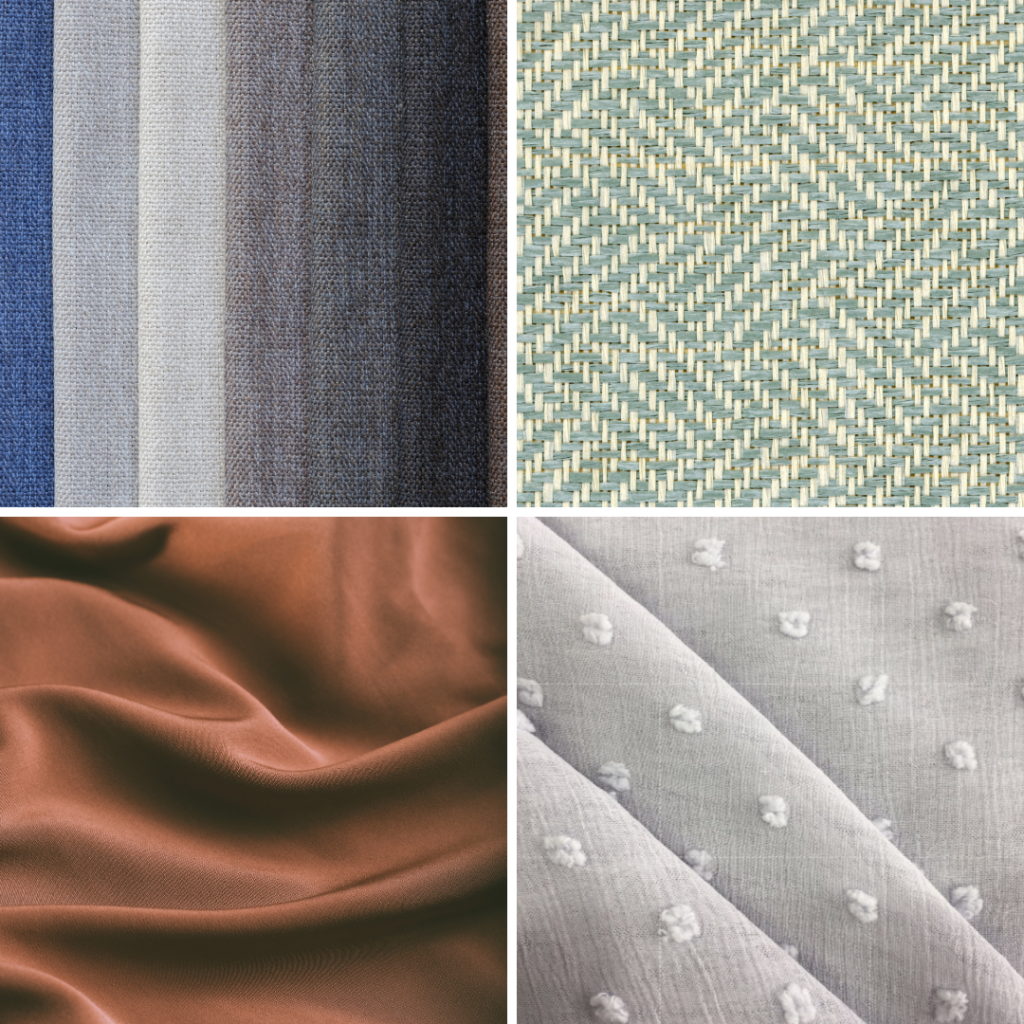

Fabric Types We Offer

- Plain Weaves – Cambric, Poplin

- Twill & Drill – Twill, Drill, Gabardine, Broken Twill

- Sateen & Satin – Stripe Satin, Sateen

- Textured Weaves – Oxford, Chambray, Rip Stop, Corduroy

- Dobby Designs – Customized patterns for fashion & home textiles

Fiber & Blends

- 100% Cotton

- Polyester-Cotton Blends

- Linen Blends

- Lycra Stretch Fabrics

From Threads to Fabric

Every piece of fabric begins as delicate threads, carefully interlaced through a precise weaving process. This intricate craftsmanship blends tradition with innovation, ensuring strength, texture, and elegance in every weave. From the rhythmic motion of the looms to the creation of smooth, flawless fabric, this journey is a testament to skill and precision.

Quality & Sustainability

At Cora Tex, we follow rigorous quality control measures to ensure flawless fabric production. We are committed to sustainability